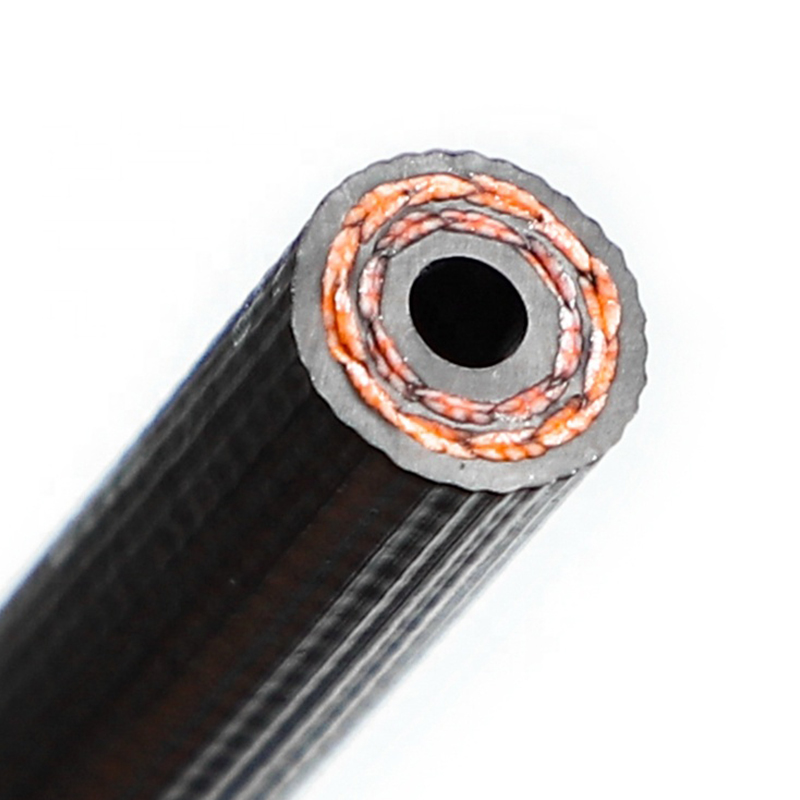

Rubber Brake Hose 1/8 sae j1401 DOT SAE Hydraulic High Pressure Brake Hose

| I.D (mm) | 3.2 |

| O.D (mm) | 10.5 |

| material | NBR |

| structure | nylon+rubber |

| size | 1/8 |

Why does the rubber brake hose has nylon braided line?

Using nylon interlayer and chlorinated butyl rubber as inner and outer layer structure, can produce a new type of hose to prevent freon gas leakage, make the pipe stronger.

Rubber aging factors:

1. Oxygen: Oxygen in rubber with rubber molecules in the free radical chain reaction, molecular chain break or excessive crosslinking, resulting in the change of rubber properties.

2. Ozone: Ozone chemical activity than oxygen is much higher, more destructive, it is also to break the molecular chain, but the action of ozone on rubber with rubber deformation is different.

3. Heat: Improve the oxygen diffusion rate and activation oxidation reaction, so as to accelerate the rubber oxidation reaction rate, which is a common aging phenomenon – thermal oxygen aging.

4. Light: The shorter the light wave, the more energetic it is. It is the high energy ultraviolet that destroys rubber. In addition to directly causing the break and cross-linking of rubber molecular chains, the rubber absorbs light energy and produces free radicals, which initiates and accelerates the oxidation chain reaction process, which is called “light outer layer crack”.

5. Water: the role of water has two aspects: rubber in wet air rain or soaked in water, easy to destroy, this is due to the water-soluble substances in rubber and hydrophilic groups and other components by water extraction and dissolution, hydrolysis or absorption and other reasons. Especially under the alternating effect of water immersion and atmospheric exposure, the destruction of rubber will be accelerated. However, in some cases, water does not destroy rubber, and even has the effect of delaying aging.

7. Oil: In the use of the process of long-term contact with oil medium, oil can penetrate into the rubber to make it swell, resulting in the reduction of rubber strength and other mechanical properties. Oil can make rubber swelling, because oil into rubber, produced molecular diffusion, so that the vulcanized rubber network structure changes.